Woven wire screen mesh is one of the important wearing parts in quarries and mining industry. In quarries, this wear-resistant woven wire screen mesh is used for screening and separating materials with different particle sizes. In the mining industry, woven wire screen mesh is used in a variety of processes such as screening and grading of ores.

Machined from high manganese steel or stainless steel, the woven wire screen mesh is strong, tensile, abrasion and corrosion resistant and is built to last in harsh environments.

Woven wire mesh screen serves several crucial purposes. It is designed to withstand the harsh conditions and heavy demands of the mining industry.

One of the primary uses is in the screening and sizing of ores and minerals. The mesh helps to separate different particle sizes, allowing for efficient processing and extraction. It ensures that only the desired sized materials pass through, while larger or unwanted particles are retained.

Woven wire screen mesh specification:

• Material:

High strength spring steel, wear resistant manganese steel (65Mn) and stainless steel.

| 65Mn main chemical elements | ||

| Chemical Element |

Content Range | Function |

| Carbon (C) | 0.62% - 0.70% | Has important influence on the strength and hardness of the steel. High carbon content can increase the strength of the steel, but will reduce its toughness. |

| Silicon (Si) | 0.17% - 0.37% | Can improve the strength and hardness of the steel and the heat treatment performance. But too high silicon content will reduce the cold working performance of the steel. |

| Manganese (Mn) | 0.90% - 1.20% | Can improve the strength and toughness of the steel and the heat treatment performance. |

| Phosphorus (P) | ≤0.035% | Too high phosphorus content will reduce the toughness and cold working performance of the steel. |

| Sulfur (S) | ≤0.035% | Too high sulfur content will reduce the plasticity and welding performance of the steel. |

• Wire diameter: 1.6mm - 16mm.

It can be inspected by rigorous micrometer testing to ensure very small diameter deviations.

• Opening size: 1mm - 100mm.

The deviation of the opening dimensions is extremely small and is controlled within 2-3%.

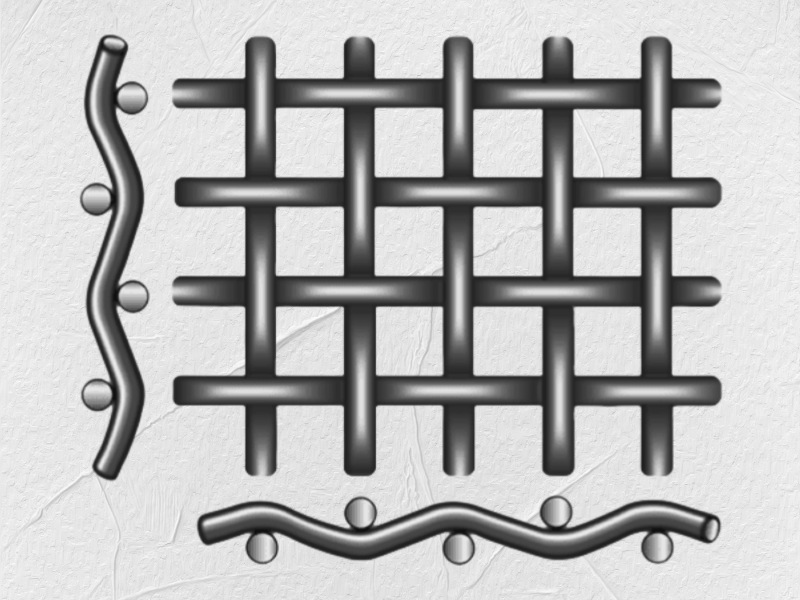

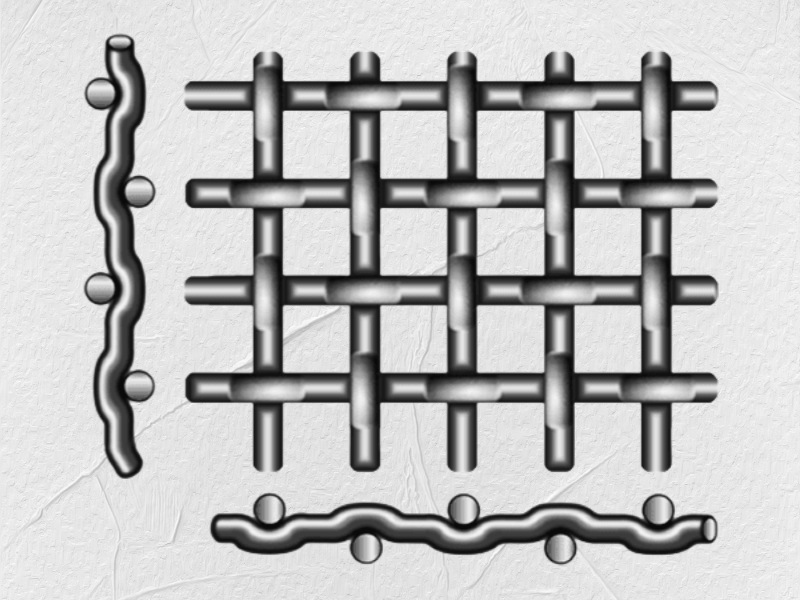

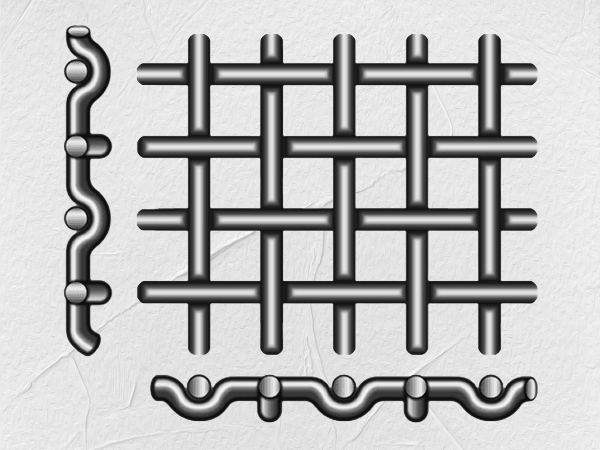

• Weaving type:

• Mesh type: Square, rectangular slot, long slot.

• Surface treatment: Black or red color painted.

• Edge preparation: Plain, bent, reinforced shroud, other.

• Hook type: C or U hook for 30° - 180°.

Woven wire mesh screen features:

• Wear-resistant, impact-resistant, no breakage for long time use.

• High tensile strength and toughness.

• Precise and uniform opening size.

• Tight and regular weave, no loose or loopholes.

• Flat mesh, no unevenness.

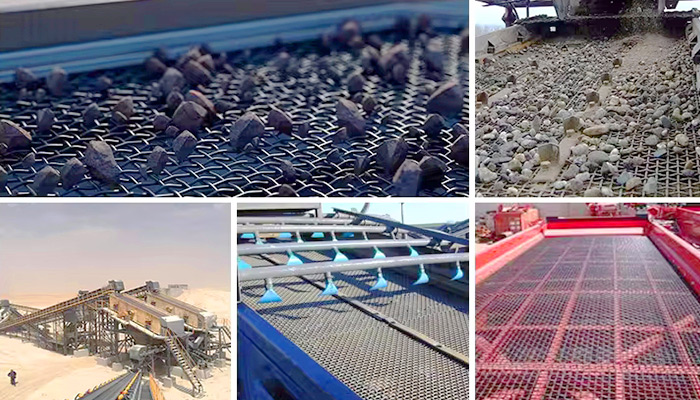

Woven wire screen mesh applications:

• Mining field: used for screening and grading ores. It can withstand the impact and abrasion of ores. It plays an important role in quarries, ore dressing plants, and other places.

• Building materials: it can be used to screen building materials such as sand and gravel to ensure that the particle size meets requirements.

• The metallurgical industry uses it to screen raw materials and finished products in iron and steel mills and to screen iron powder.

• Chemical industry: it can be used to filter impurities in chemicals.

• Grain processing: It is used to clean and grade grain, separating grains with different particle sizes.

• It is used in sewage and solid waste treatment.

• It can be used to screen seeds and fertilizers.

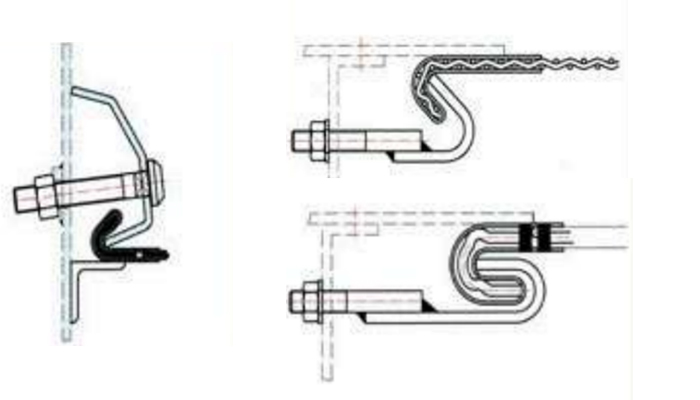

Wear resistant woven wire screen mesh for quarry and mining industry Installation Notes:

In order to ensure the normal service life of the screen mesh, wear resistant woven wire screen mesh for quarry and mining industry must be tensioned during installation. The dimensions and curved edges of the screen mesh must match the corresponding dimensions and shapes of the screening machines and tensioning plates. As shown below:

Customized Service:

• Reliable quality

• Cost-effective

• Full technical support

• OEM available

• Product test reports