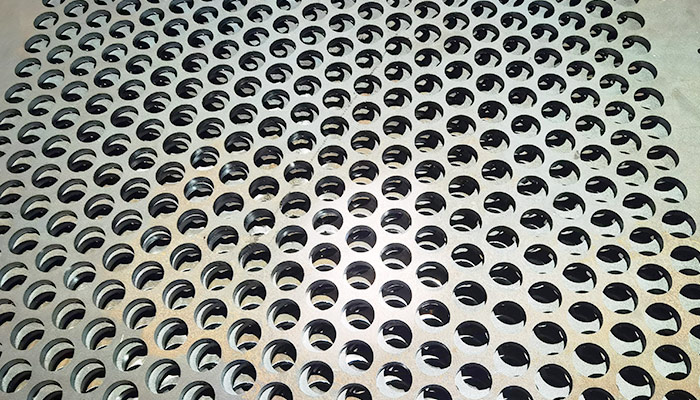

The trommel screen and vibrating screen perforated plates, machined from wear-resistant steel (NM400-NM500), have a smooth surface that ensures efficient screening and separation with less hooking and clogging.

The holes of the perforated plates can be customised in round, hexagonal, oval, square, rectangular or other shapes, depending on the screening process.

The trommel screen and vibrating screen perforated plates are generally made of wear-resistant steel plates (NM400, NM450, NM500, thickness 10-12mm) specialised for construction machinery, which are processed by laser cutting, perforating and rolling.

Due to the corrosion resistance, abrasion resistance and high hardness of the wear-resistant steel plate itself, it can effectively withstand the impact of heavy loads from the feeder when applied to vibrating screens and trommel screens.

Due to the high hardness of wear-resistant steel, perforated plates are generally not designed with mounting holes, but with other connection methods. However, in some cases, trommel screens designed with countersunk holes need to be drilled, so higher hardness drills must be used.

The trommel screen perforated plates in the rolling process, need to use a higher strength and power of the four-roller plate rolling machine, in order to make the rolled trommel screens have a good curvature to install on the trommel screens.

Materials:

NM400, NM450, NM500 or any other.

Applications:

The trommel screen and vibrating screen perforated plates are widely used in crushed stone quarries, sand and gravel plants, coal beneficiation plants, phosphorus, iron or copper mines to screen and separate stone, coal, gravel or sand.

Customised Service:

• Dimensions according to customer drawings.

• The material is specified by the customer.

• The trommel screen perforated plates have a maximum size of 12mm thickness.

• Provide a certificate for the raw material of the wear-resistant material.

• Provide test reports.

Customise your perforated plates to fit perfectly on your vibrating screens and trommel screens from a professional supplier.