Pneumatic conveying is a technology that uses airflow as a driving force to convey materials in pipelines. It is an effective solution for long-distance conveying and can handle a variety of materials, including powder and granules. The closed conveying process minimises pollution and loss of materials, making it a sustainable choice.

CAFU Machinery is a professional designer of pneumatic conveying system and a high-quality supplier of its system equipment.

Our equipment is widely used in a number of industrial sectors, including power generation, mineral processing, powder material handling and the cement industry. Specific applications include boiler dry ash removal, desulphurisation limestone powder conveying, kiln powder conveying, biopower plant fly ash conveying, negative pressure pneumatic conveying of copper powder, cement clinker transfer conveying and so on.

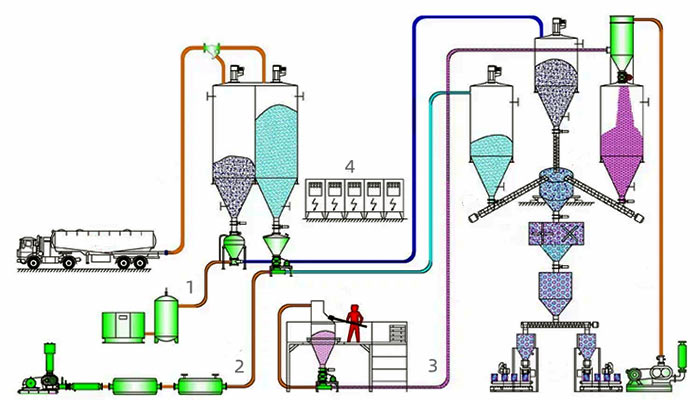

Dense Phase Pneumatic Conveying System

The positive pressure dense phase (bin pump) pneumatic conveying system is an advanced and reliable dry conveying system, offering a high level of reliability and performance.

The system boasts the following main features:

• The system is designed to operate at low flow rates, which minimises wear on the pipework.

• The system has low energy consumption and low running costs.

• The system is designed to prevent ash clogging and operates fully automatically.

• The system boasts a large ash/gas ratio.

• The product is designed for transportation over long distances, up to 1500 metres.

• The material is transported in the pipeline in an environmentally friendly manner, with no pollution or leakage.

The following conditions apply to the usage of the product:

• The air source is compressed air.

• The conveying pump has a volume range of 0.5 to 30 cubic metres.

• The maximum output is 260-300t (clinker).

• The maximum conveying distance is 1,500 metres.

• The ash conveying pipe comprises a seamless steel pipe and a wear-resistant ceramic elbow.

• The control system comprises a PLC and a touch screen, or alternatively, a PLC and an upper computer.

The system is designed for use in the following applications:

This system is ideal for long-distance and high-capacity conveying, and is suitable for the transportation of cement, fly ash, mineral powder, chemical raw materials and other abrasive materials.

Dilute Phase Pneumatic Conveying

This system uses a roots blower installed at the beginning of the conveying system to pass positive pressure air above atmospheric pressure into the feeder, where the material is added from the hopper and enters the feeder under the effect of gravity for quantitative feeding. The material and air are transported together through the conveying pipe to the separator or storage bin at the end of the system. After the material and air are separated, the air is filtered and discharged into the atmosphere.

This system is a kind of pneumatic conveying system with Roots blower as the air source and rotary feeder (or screw pump, AV pump, etc.) as the feeding device to continuously convey materials. The system has the points of low conveying pressure, short conveying distance and reliable conveying. Because the system is positive pressure, so even if there is a gap in the pipeline system, the outside air or rain will not intrude, and the material is easy to be discharged from the discharge port.

System Features:

• Simple structure, reliable operation, stable conveying, simple operation, convenient and flexible arrangement.

• The quality requirement for air source is not high, and the system is highly reliable. The air source can be Roots blower or centrifugal fan. However, the performance of Roots blower determines the reliability of the system.

• Fully sealed, non-polluting conveying, meets its own environmental protection and engineering requirements for the quality of the materials conveyed. Due to the positive pressure conveying, the outside material can not enter into the pipeline, so it will not cause any change of the nature of the material, and the conveying quality is high.

System Application:

• The products are widely used in electric power, metallurgy, petrochemical, plastic, food, building materials and hydropower industry. The conveying pipeline can be arranged according to the specific terrain to achieve centralised, decentralised, large-height and long-distance conveying. The conveying process is not affected by weather conditions, which ensures that the materials are not damp and is conducive to health and environmental protection.

• It is suitable for conveying fly ash, cement raw material, mineral powder, limestone powder, plastic and rubber granule, alumina powder and so on.

High and low pressure dilute phase pneumatic conveying is a kind of pneumatic conveying system, all belong to the use of air pneumatic principle, the energy of the air flow, in the closed pipe along the direction of the air flow conveying powder or granular materials, is a specific application of fluidisation technology.

Performance Range:

• Conveying pressure: 100-600Kpa

• Conveying capacity: 0.1-120t/h

• Conveying distance: <1000m

• Conveying pipe diameter: 40-200mm

For further details regarding our pneumatic conveying system solutions, please do not hesitate to contact our customer service team.

CAFU Machinery employs a team of highly experienced engineers specialising in pneumatic conveying system. We offer complimentary design consultancy services to our clients. If you require our assistance, please do not hesitate to contact us at any time. We will work with you to provide the optimal pneumatic conveying solution for your bulk material handling needs.