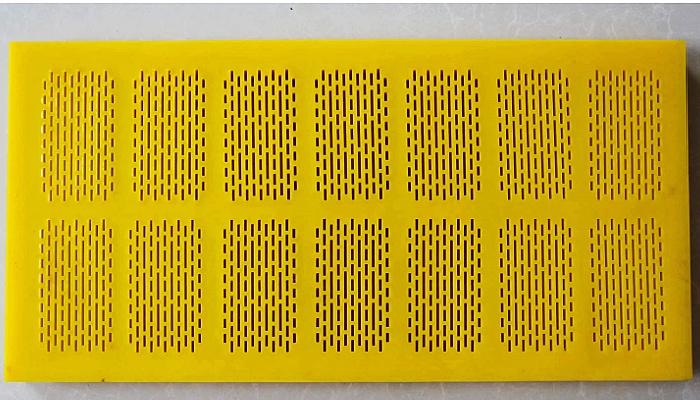

The mineral beneficiation vibrating screen polyurethane screen mesh, abbreviated as PU screen, is a new type of product developed in recent years to replace metal screen panels ( screen mesh ) on the screening machine for ore dressing, classification, dewatering and so on in the mines. Due to its good wear resistance, long service life, moisture resistance and good wear resistance, it is mainly used in coal mine, iron ore mine, copper mine, gold mine and other kinds of ore classification, screening, dewatering and other places, and it is one of the necessary accessories of vibrating screen.

Value of mineral beneficiation vibrating screen polyurethane screen mesh:

Among the many mineral beneficiation polyurethane screen mesh available, our customised polyurethane screen panels have proven to be highly effective in screening copper, gold, molybdenum, phosphate, iron ore, limestone and aggregates in a wide range of industries.

Our extensive experience in the industry will help our polyurethane screen mesh to work with your vibrating screen to extend the life of the screen panels and reduce operating costs for you and your shareholders.

Type of structure of mineral beneficiation vibrating screen polyurethane screen mesh:

• Inlay type

• Bolt connection

• Batten coupling

• Screen hook connection

Feature:

• The mineral beneficiation vibrating screen polyurethane screen mesh offers excellent abrasion resistance and a long service life, which is more than ten times that of metal screen mesh, three to five times that of a common rubber plate, and two to three times that of stainless steel.

• The cost of tonnes of ore consumption is lower than that of metal screen mesh.

• The product is highly resistant to moisture and abrasion.

• The polyurethane screen mesh offers superior shock absorption and noise reduction, with a reduction of over 10dB compared to metal screen mesh.

• The polyurethane secondary vibration characteristics result in excellent automatic cleaning, with no blocking and high screening efficiency.

Customised service:

• Reliable quality

• Cost-effective

• Full technical support

• OEM available

• Product test reports

Please do not hesitate to contact our professional team to customise your mineral beneficiation vibrating screen polyurethane screen mesh.