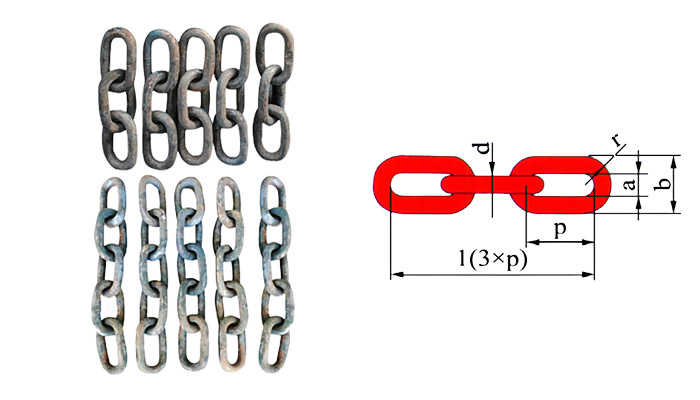

The mine car three-link chain and five-link chain is a crucial component utilized in the configuration of underground coal mines. Typically, these chains are crafted from high-strength metals and exhibit a three-ring structure. They serve as vital links in the coal mine transport system, connecting various mine cars and ensuring uninterrupted transportation.

Download Product Brochure ⇒ Round Steel Chains and Chain Shackle and Fittings

Product features of mine car three and five link chains:

-Application: Mine car connection

-Material: High quality alloy steel

-Production standard: ISO, DIN, BS, CB, MT and other standards.

-Strength grade: C grade, B grade

-Safety guarantee: Test load is 2 times working load.

Size and Mechanical Property

Our mine car three and five link chains are available in a range of sizes and strengths, including Grade 100 (Grade D) and Grade 80 (Grade C). In withstanding the huge tensile force when the mine car is fully loaded with coal, as well as long-term and frequent pulling, collision and other complex working conditions, it is still able to maintain structural integrity, effectively avoiding the occurrence of rupture and so on, so as to ensure the safety and stability of the underground transport work in coal mines.

| Spec. d×p (mm) |

Width Min. a (mm) |

width Max. b (mm) |

Mass (kg/set≈) |

Radius r (mm) |

Proof force (kN) |

Breaking force (kN) |

Max. elongation at proof force % |

Min. elongation at breaking force % |

| 22×105 | 40 | 87 | 2.9 | 41 | 70 | 370 | 2 | 15 |

| 26×118 | 46 | 102 | 4.6 | 48 | 100 | 520 | 2 | 15 |

| 28×120 | 48 | 108 | 6.7 | 51 | 110 | 610 | 2 | 15 |

| 30×120 | 48 | 112 | 7.8 | 53 | 120 | 670 | 2 | 15 |

| 30×130 | 55 | 119 | 6.9 | 56.5 | 120 | 670 | 2 | 15 |

| 32×140 | 58 | 126 | 9.9 | 60 | 140 | 790 | 2 | 15 |

| 34×147 | 64 | 136 | 10.1 | 65 | 160 | 890 | 2 | 15 |

| 38×145 | 80 | 160 | 13.65 | 77 | 200 | 1110 | 2 | 15 |

Product Advantage:

• Utilization of high-quality raw materials.

• High strength and excellent toughness.

• High capacity for absorbing impact loads.

• 100% factory testing.

• Employment of advanced production equipment.

• Adoption of advanced heat treatment process and surface anti-rust treatment.

Please contact us now to discuss what you need.