The High Strength Compact Chain for Mining is important in mining, especially coal mining. It is used in many essential machines, including scraper conveyors, coal mining machines, tunneling machines, and coal ploughs. This chain is a key part of the scraper conveyor. Its design makes it stand out. The flat rings are circular, while the vertical rings are flat. The outer width of the vertical ring is smaller than that of the flat ring. When height limitations prevent the use of larger chains in conveyors, our compact chain can meet the requirements perfectly.

Download Product Brochure ⇒ Round Steel Chains and Chain Shackle and Fittings

In the mining sector, the High Strength Compact Chain for Mining is a crucial product, particularly in coal mining operations. It is used extensively in a number of essential pieces of equipment, including scraper conveyors, scraper transfer machines, coal mining machines, tunneling machines, and coal ploughs.

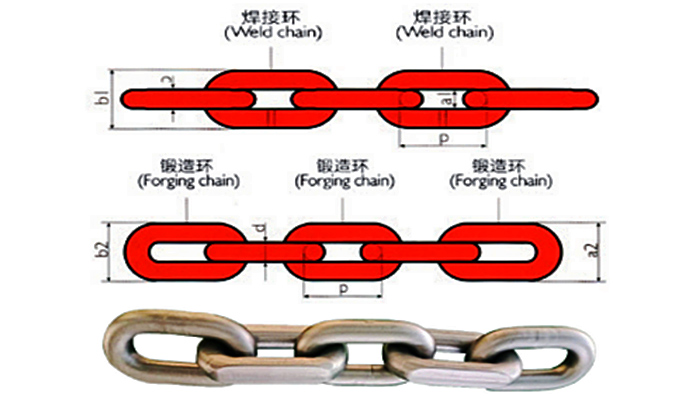

As a crucial yet susceptible component of the scraper conveyor, the compact chain stands out due to its distinctive design. In particular, the flat rings of this chain retain a circular configuration, while the vertical rings are flat. Furthermore, the outer width of the vertical ring is less than that of the flat ring.

In instances where height restrictions prevent the use of larger round-link chains in conveyors, our compact chain, with identical specifications, can fulfil the required criteria precisely. This enables conveyors to operate at an optimal level, ensuring smooth and efficient mining processes.

Material: High-quality alloy steel (23MnNiMoCr54)

We select high-quality alloy steel to manufacture our compact chain for mining. This material endows the chain with excellent durability and strength, ensuring it can withstand the harsh conditions in the mining environment and heavy loads during operation, thus prolonging its service life.

Size and Mechanical Property

Our compact chains are available in a range of sizes and strength grades, including Grade 100 (Grade D) and Grade 80 (Grade C). These options are designed to meet the diverse demands of different mining equipment, providing reliable mechanical performance to ensure smooth mining processes.

| Spec. d×p (mm) |

Diameter d (mm) |

Pitch p (mm) |

Width Max. c (mm) |

Inner width Max. a (mm) |

Max. b1 (mm) |

Max. b2 (mm) |

Mass (kg/m≈) |

Radius r (mm) |

Proof force (kN) |

Breaking force (kN) |

Max. elongation at proof force % |

Max. elongation at breaking force % |

Quality grade |

| 22×86 | 22±0.7 | 86±0.9 | 26 | 26 | 77 | 60 | 8.9 | - | 490 | 610 | - | - | C |

| 610 | 760 | - | - | D | |||||||||

| 26×92 | 26±0.8 | 92±0.9 | 27 | 30 | 86 | 74 | 13.7 | 40 | 680 | 850 | 1.6 | 12 | C |

| 850 | 1060 | 1.9 | 12 | D | |||||||||

| 30×108 | 30±0.9 | 108±1 | 33 | 34 | 98 | 86 | 18 | 46 | 900 | 1130 | 1.6 | 12 | C |

| 1130 | 1410 | 1.9 | 12 | D | |||||||||

| 34×126 | 34±1 | 126±1.2 | 37 | 38 | 109 | 97 | 22.7 | 52 | 1160 | 1450 | 1.6 | 12 | C |

| 1450 | 1810 | 1.9 | 12 | D | |||||||||

| 38×126 | 34±1.1 | 126±1.4 | 42 | 42 | 121 | 110 | 29.4 | 58 | 1450 | 1810 | 1.6 | 12 | C |

| 1810 | 2270 | 1.9 | 12 | D | |||||||||

| 38×137 | 38±1.1 | 137±1.4 | 42 | 42 | 121 | 110 | 28.5 | 58 | 1450 | 1810 | 1.6 | 12 | C |

| 1810 | 2270 | 1.9 | 12 | D | |||||||||

| 38×146 | 38±1.1 | 146±1.5 | 42 | 42 | 121 | 110 | 28.4 | 58 | 1450 | 1810 | 1.6 | 12 | C |

| 1810 | 2270 | 1.9 | 12 | D | |||||||||

| 42×146 | 42±1.3 | 146±1.5 | 46 | 46 | 135 | 115 | 37 | 64 | 1770 | 2220 | 1.6 | 12 | C |

| 2220 | 2270 | 1.9 | 12 | D | |||||||||

| 42×152 | 42±1.3 | 152±1.5 | 46 | 46 | 135 | 127 | 35 | 64 | 1770 | 2220 | 1.6 | 12 | C |

| 2220 | 2760 | 1.9 | 12 | D | |||||||||

| 48×152 | 42±1.4 | 152±1.5 | 56 | F=62 V=53 | 162 | 127 | 46.8 | 79 | 2300 | 2890 | 1.6 | 12 | C |

| 2900 | 3610 | 1.9 | 12 | D |

Customization standards: ISO, DIN, BS, GB and other standards

Product Advantage:

• Utilization of high-quality raw materials.

• High strength and excellent toughness.

• High capacity for absorbing impact loads.

• 100% factory testing.

• Employment of advanced production equipment.

• Adoption of advanced heat treatment process and surface anti-rust treatment.