Heavy Duty Apron Feeder & Heavy Duty Apron Conveyor & Heavy Duty Reclaim Feeder Conveyor

The production capacity is as follows:

The standard model has a throughput capacity of up to 2050 TPH, while the custom model can handle up to 4000 TPH.

Conveyor lengths up to 80,000 mm.

The Heavy Duty Apron Feeder Conveyor is Your Heavy Duty Machinery of Choice for Handling Bulky Materials.

The Heavy Duty Apron Feeder Conveyor is a reliable solution for handling heavy materials. With its robust construction and efficient operation, it ensures seamless material transfer, making it ideal for industries like mining and construction, where durability and high performance are essential.

It is a kind of continuous conveying machine widely used in mining, metallurgy, building materials, port, coal and chemicalindustries. It is mainly used to supply and transfer all kinds of bulk materials continuously and uniformly from storage silo or hopper to crusher, batching plant or conveying equipment. It is one of the important and indispensable equipment in ore and raw material processing and continuous production process.

CAFU CFHP Series Heavy Duty Apron Feeder Conveyor

| Width(mm) | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 2500 | 2600 |

| Centre Distance(mm) | 1500-80000 | ||||||||

| Capacity(t/h) | 450 | 750 | 900 | 1000 | 1080 | 1200 | 1850 | 1960 | 2050 |

| Installation Angle(°) | 0-25 | ||||||||

| Speed(m/s) | 0.05-0.2 | ||||||||

| Max. Feed Size(mm) | 600 | 760 | 880 | 990 | 1300 | 1430 | 1560 | 1625 | 1690 |

Relatively Low Total Cost of Ownership

Reducing TCO is the goal from the time of purchase to the time of use.

• Customised for specific applications including mining, cement plants, ports, aggregate crushing, steel plants, power plants.

• The average service life is more than 15 years.

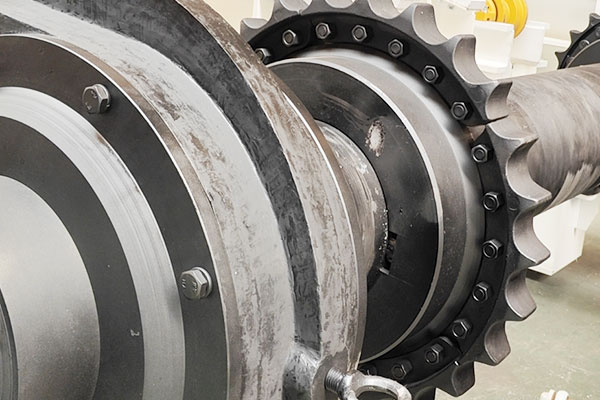

Technical Features

• Allow the bulk density of the material is 1~2.4t/m3.

• The max. block size of the permitted materials is 2m.

• The maximum capacity of silo is 500t.

• The maximum temperature of material is 300℃.

• The feeder has the function of starting with 15% overload.

• The feeder has the ability to operate reliably under continuous work and heavy load conditions.

• Long service life, the whole machine operation period is more than 15 years.

• The conveying chute for transporting materials is rigid, with high impact performance and good wear-resisting performance.

• Good airtight performance, no spilling and leakage of materials in the process of operation and unloading.

• All adopt rolling bearings, the whole machine has the characteristics of small running resistance, easy maintenance and high efficiency.

• The whole machine has compact structure, smooth operation and low noise.

• It has the function of mechanical and electrical double overload automatic protection.

Product Advantage

CAFU's Professional Services Guarantee

• Rapid delivery capability

• Global installation supervision

• Complete spare parts supply guarantee programme

Three Reasons Choose CAFU-Our Core Advantages

Contact us now to increase your production capacity with our CFHP series heavy duty apron feeder conveyor.