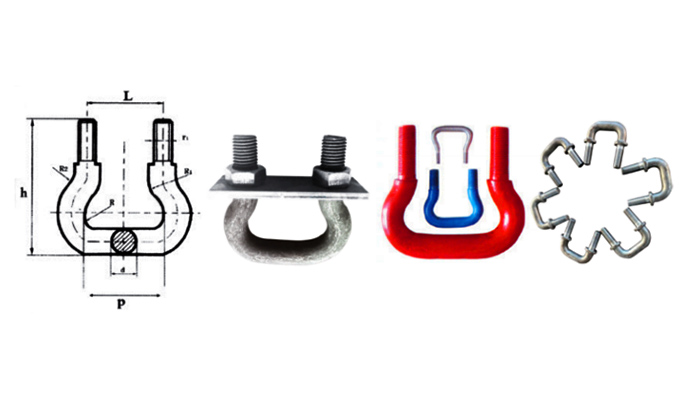

There are several types of round steel chain fittings. End links include open-ended connecting link, dwarf groove V-lock chain link, flat type chain link, curved tooth connecting link and serrated connecting link, and for bucket chain shackles for buckets, etc.

Download Product Brochure ⇒ Round Steel Chains and Chain Shackle and Fittings

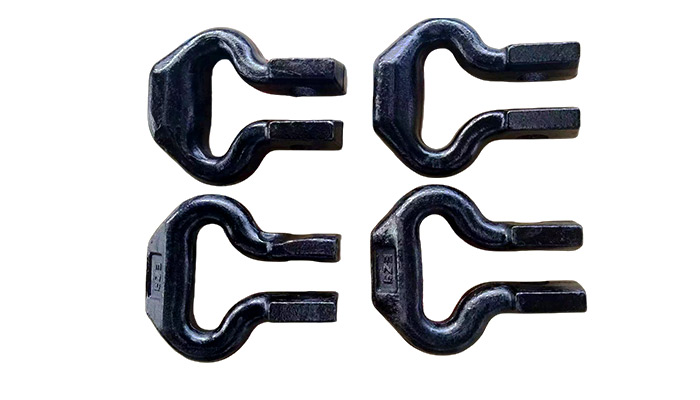

• Open-ended Connecting Link

It is applicable to the connecting link used in the side double scraper conveyor and transfer conveyor under the coal mine. This connecting link is connected with the mining high-strength circular chain and scraper.

Size & Mechanical Properties(MT/T71-1997)

| Spec. | p (mm) |

b (mm) |

Proof force for B grade (kN) |

Breaking force for C grade (kN) |

| ∅10×40 | 40±0.3 | 12±0.5 | 80 | 90 |

| 100 | 120 | |||

| ∅14×50 | 50±0.5 | 16±0.5 | 136 | 170 |

| 180 | 225 | |||

| ∅18×64 | 64±0.6 | 20±0.5 | 232 | 290 |

| 300 | 370 | |||

| ∅22×86 | 86±1 | 23±1 | - | - |

| 415 | 550 | |||

| ∅26×92 | 92±1 | 27±1 | - | - |

| 575 | 765 | |||

| ∅30×108 | 108±1 | 31±1 | - | - |

| 706 | 990 |

Material: high quality alloy steel

• Curved Tooth Connecting Link

Curved tooth chain links are used to connect vertical or horizontal mining chains, but can also be used on scraper conveyors and coal planers.

The choice of special materials and the small tolerances ensure that the curved tooth coupling rings are not only easy to install, but also have a better performance than the DIN chain Link.

Size & Mechanical Properties

| Spec. | Max. d (mm) |

Max. t (mm) |

Proof force (kN) |

Breaking force (kN) |

Workload force (kN) |

Mass (kg) |

| 22×86 | 22±0.7 | 86±0.9 | 455 | 645 | 380 | 1.35 |

| 26×92 | 26±0.8 | 92±0.9 | 637 | 900 | 531 | 1.92 |

| 30×108 | 30±0.9 | 108±1.1 | 848 | 1200 | 707 | 2.98 |

| 34×126 | 34±1.0 | 126±1.3 | 1090 | 1540 | 907 | 4.15 |

| 38×137 | 38±1.1 | 137±1.4 | 1360 | 1926 | 1130 | 5.71 |

| 42×146 | 42±1.1 | 146±1.5 | 1660 | 2210 | 1990 | 7.2 |

Material: high quality alloy steel

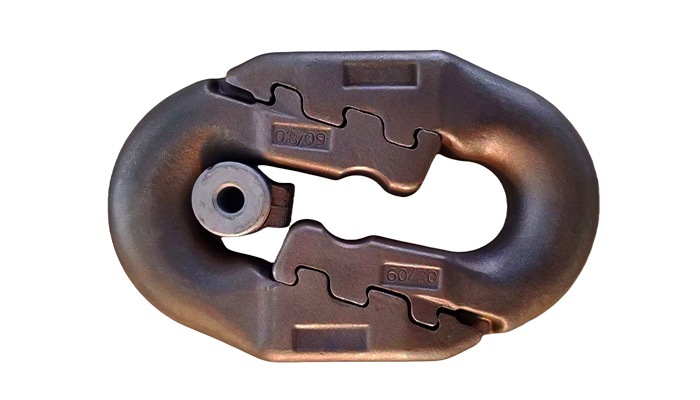

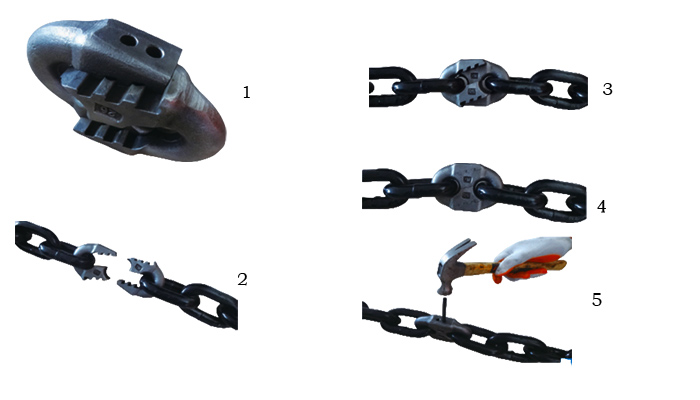

• Serrated Connecting Link

This product is suitable for connecting links between mining round chains, which can be installed both horizontally and vertically. It conforms to NT/T99-1997 standard, with precise tooth shape and easy disassembling and assembling.

Size & Mechanical Properties

| Spec. | P (mm) |

Proof force (kN) |

Breaking force (kN) |

Tensile load (kN) |

Mass (kg) |

| 18×64 | 64±0.6 | 330 | ≥370 | 330-340 | 0.73 |

| 22×86 | 86±0.9 | 490 | ≥550 | 490-510 | 1.50 |

| 24×86 | 86±0.9 | 580 | ≥650 | 580-600 | 1.52 |

| 26×92 | 92±0.9 | 640 | ≥770 | 640-700 | 1.92 |

| 30×108 | 108±1.1 | 850 | ≥1020 | 850-900 | 3.10 |

| 34×126 | 126±1.3 | 1080 | ≥1300 | 1080-1200 | 4.50 |

| 38×137 | 137±1.4 | 1360 | ≥1630 | 1360-1500 | 5.65 |

| 48×152 | 152±1.5 | 1660 | ≥2000 | 1660-1800 | 7.50 |

Material: high quality alloy steel

Installation Example

• Dwarf Groove V-Lock Chain Link

Dwarf groove V-Lock chain link can be used to connect round steel link and Compact Chain as well as F-class chain.

They have very high tensile properties and fatigue life due to the use of high-alloyed raw materials enriched with Cr, Ni and Mo elements and multiple heat treatment processes in the manufacturing process.

These links can only be used vertically and their dimensions are in accordance with DIN 22258 Part 3.

Size & Mechanical Properties

| Spec. d×p (mm) |

Code | Max. L (mm) |

Max. T (mm) |

Min. V (mm) |

Max. W (mm) |

Mass (kg≈) |

Proof force (kN) |

Breaking force (Min. kN) |

Fatigue life test cycle Min. |

Elastic pin code |

| 26×92 | C2910F | 213 | 28 | 28 | 64 | 2.5 | 690 | 960 | 100000 | XV0503 |

| 30×108 | C2021 | 241 | 32 | 32 | 79 | 3.3 | 920 | 1270 | 100000 | XV0503 |

| 34×126 | C2927F | 292 | 36 | 36 | 87 | 4.7 | 1360 | 1700 | 100000 | XV0503 |

| 38×137 | C2937F | 302 | 40 | 40 | 98 | 5.9 | 1520 | 1900 | 100000 | XV0503 |

| 42×146 | C2931F | 330 | 44 | 44 | 107 | 7.5 | 1840 | 2300 | 100000 | XV0503 |

| 48×152 | C2992F | 331 | 56 | 53 | 115 | 9.15 | 2170 | 2900 | 100000 | XV0503 |

Material: high quality alloy steel

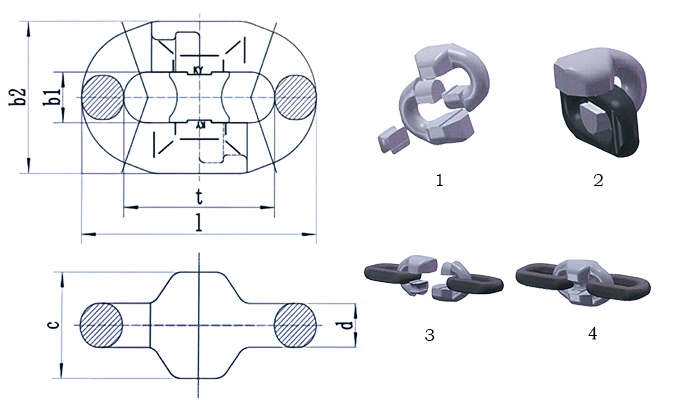

• Mining Flat Type Chain Link

Mining flat type chain link can only be used for horizontal installation to match with the sprocket, and it can be fully used with D grade chain. It is specially designed for connecting round chain and compact chain, with good matching structure, easy to disassemble and assemble, the external dimensions are in accordance with DIN 22258 Part2 standard, and its mechanical properties are much higher than DIN 22258 Part2 standard.

High quality alloy steel is chosen as the raw material for anti-corrosion and wear-resistant in the production process, and the heat treatment is carried out in ‘controlled atmosphere multi-purpose furnace’ to prevent deformation and oxidative decarburisation of the chain links in the heat treatment process, so that they have very high mechanical properties and fatigue life.

Size & Mechanical Properties

| Spec. d×p (mm) |

Code | tq±0.5 (mm) |

Max. l (mm) |

Max. c (mm) |

Min. b1 (mm) |

Max. b2 (mm) |

Mass (kg≈) |

Proof force (kN) |

Breaking force (Min. kN) |

Fatigue life test cycle |

| 22×86 | K22P | 86 | 131 | 55 | 28 | 85 | 1.9 | 525 | 755 | 1000000 |

| 26×92 | K26P | 92 | 146 | 66 | 30 | 95 | 2.5 | 735 | 1060 | 1000000 |

| 30×108 | K30P | 108 | 169 | 74 | 34 | 110 | 3.9 | 990 | 1410 | 1000000 |

| 34×126 | K34P | 126 | 195 | 86 | 36 | 121 | 5.9 | 1250 | 1800 | 1000000 |

| 38×126 | K38P126 | 126 | 204 | 94 | 43 | 135 | 7.0 | 1560 | 2250 | 1000000 |

| 38×137 | K28P | 137 | 214 | 94 | 43 | 135 | 8.0 | 1560 | 2250 | 1000000 |

| 38×146 | K28P146 | 146 | 225 | 94 | 43 | 135 | 9.0 | 1560 | 2250 | 1000000 |

| 42×146 | K42P | 146 | 231 | 104 | 466 | 148 | 11 | 1930 | 2720 | 1000000 |

| 48×152 | K48P | 152 | 249 | 120 | 54 | 169 | 13.8 | 2450 | 3550 | 1000000 |

Material: high quality alloy steel

• Chain Shackle

Main Specification Size

| Spec. dxp (mm) |

d (mm) |

Pitch p (mm) |

Outer width (mm) |

Center distance L (mm) |

Thread length (mm) |

Total length h (mm) |

| 14*50 | 14±0.4 | 50±0.8 | 78 | 35±0.5 | 22 | 90±1 |

| 18*50 | 18±0.4 | 50±1.25 | 86 | 45±0.5 | 25 | 89±1 |

| 18*64 | 18±0.4 | 64±0.6 | 100 | 64±0.6 | 27 | 89±1 |

| 18*64/40 | 18±0.5 | 64 | 100 | 40±1 | 27 | 89±1 |

| 20*70 | 20±0.5 | 70±0.5 | 116 | 70±0.5 | 45 | 125 |

| 20*64 | 20±0.5 | 64±0.6 | 104 | 64±0.6 | 22 | 91±1 |

| 22*70 | 22±0.5 | 70±0.6 | 114 | 70±0.6 | 40 | 113±1 |

| 22*76 | 22±0.5 | 76±0.6 | 120 | 70±0.5 | 41 | 119±1 |

| 22*86 | 22±0.5 | 86±0.9 | 130 | 86±0.9 | 33 | 105 |

| 26*92 | 26±0.8 | 92±1.0 | 144 | 92±1.0 | 47 | 146 |

★In addition to the above common models, we can also customize other sizes of Chain shackles according to Chain shackles DIN 745/5699.

Product Advantage:

• Utilization of high-quality raw materials.

• High strength and excellent toughness.

• High capacity for absorbing impact loads.

• Employment of advanced production equipment.

• Adoption of advanced heat treatment process and surface anti-rust treatment.