CAFU Machinery's crawler drive structure medium type apron feeder is designed for aggregate crushing in mobile crushing plants and small stationary mining crushing sites. The enhanced heavy-duty design provides a longer lifespan and a more uniform feed than typical apron feeders. The advanced structural design sets our products apart from competitors in terms of quality control and user experience, making them the optimal choice for crushing plant system equipment.

Download Brochure⇒CFP Series Apron Feeders

This crawler drive structure medium type apron feeder has been developed with the specific purpose of handling material destined for the shovel loader.

Medium duty chain apron feeder are designed for shovel loader incoming material and require specific features and considerations to ensure efficient and reliable operation.

Material Handling Capacity

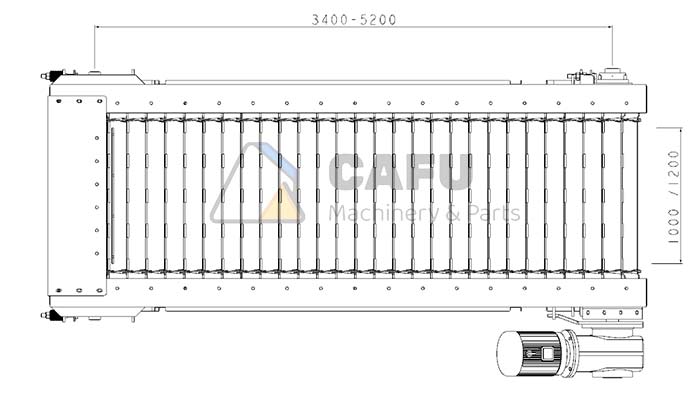

The Medium duty chain plate feeder is designed to handle the large volumes of material and variable flow rates conveyed by the shovel loader. It is essential to ensure that the width, length and speed of the feeder are properly sized to accommodate the maximum loading rate expected, while avoiding congestion or spilling.

CFP Series Apron Feeder

| Type | Size(mm) | Power(kw) | Max. Feed Size(mm) | Capacity (tph) | Speed(m/s) | Tilt Angle(°) |

| CFP1034 | 1000x3400 | 11 | 500 | 250-400 | 0-0.3 | 0-20 |

| CFP1038 | 1000x3800 | 11 | 500 | 250-400 | 0-0.3 | 0-20 |

| CFP1043 | 1000x4300 | 15 | 500 | 250-400 | 0-0.3 | 0-20 |

| CFP1052 | 1000x5200 | 22(2x11) | 500 | 250-400 | 0-0.3 | 0-20 |

| CFP1234 | 1200x3400 | 15 | 600 | 250-500 | 0-0.3 | 0-20 |

| CFP1238 | 1200x3800 | 15 | 600 | 250-500 | 0-0.3 | 0-20 |

| CFP1243 | 1200x4300 | 22(2x11) | 600 | 250-500 | 0-0.3 | 0-20 |

| CFP1252 | 1200x5200 | 30(2x15) | 600 | 250-500 | 0-0.3 | 0-20 |

Structural Durability

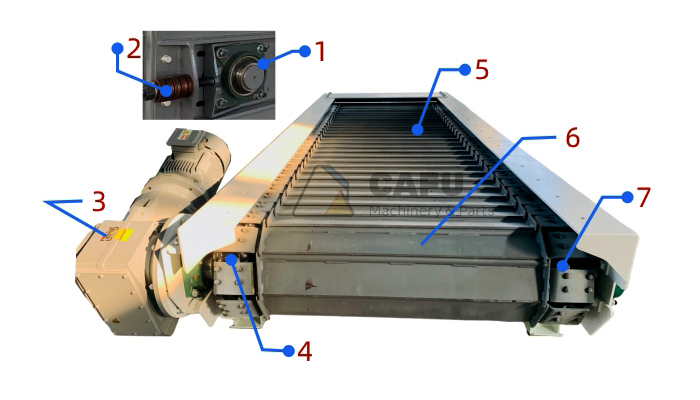

The product is constructed with heavy-duty components to withstand the impact and abrasion characteristics of the material. The skirts, chains, chain plates and support structures are constructed from high-strength, wear-resistant materials to ensure a long service life under harsh operating conditions.

1. UCFX series heavy-duty bearings; 2. Heavy-duty disc spring tensioning; 3. Electric or hydraulic drive; 4. High-strength sprockets; 5. Double-row drag chain structure; 6. Abrasion-resistant steel plate, long service life; 7. Crawler excavator chain

Custom Hoppers

Our hoppers can be customised to suit a variety of shovel loaders, ensuring a precise fit for your specific requirements.

The custom hopper can be manufactured to suit the dimensions of your shovel loader. It is capable of withstanding material from your shovel loader. The robust construction is designed and lined with wear-resistant steel plates to absorb the impact of falling material and prevent damage to the apron feeder.

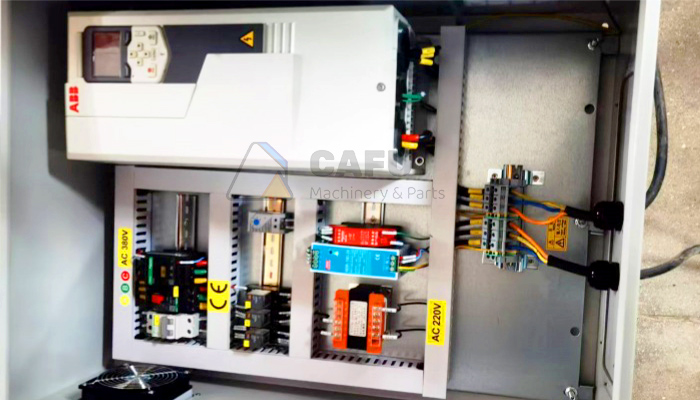

Speed Control & Adjustability

Our CFP series crawler drive structure medium type apron feeder represents an enhanced version of our feeding device. Variable speed drives are fitted as standard throughout the range, using high-performance variable frequency motors and variable frequency controllers in order to ensure precise control of the feed rate. This adjustability allows the feeder to be tailored to the output requirements of downstream processes, thereby optimising the overall material handling system.

Highly Reliable Operation, Essentially Maintenance-Free

It is essential that the product is straightforward to maintain and operate. Our products are manufactured with the highest quality components, including chains, sprockets and bearings. All components are "sealed for life and self-lubricating", eliminating the need for regular lubrication.

Three Reasons Choose CAFU-Our Core Advantages

The CAFU Machinery CFP series apron feeder is the optimal solution for the majority of crushing stations to transport Shovel Loader incoming material. Many users have provided positive feedback on our products, citing excellent performance in terms of even material feeding, stability, and resistance to impact and abrasion. Please do not hesitate to contact us at any time to discuss your specific requirements and to arrange for the provision of a customised feeder for your crushing plant.