The dense phase ash handling system is an advanced fly ash conveying technology. It uses low speed and high concentration to convey fly ash in the pipe in the form of embolism to the final collection silo. It has the advantages of high conveying efficiency, low energy consumption and low pipe wear, etc. It is widely used in large thermal power plants and other places, which can effectively handle a large amount of fly ash and improve environmental protection and economic benefits.

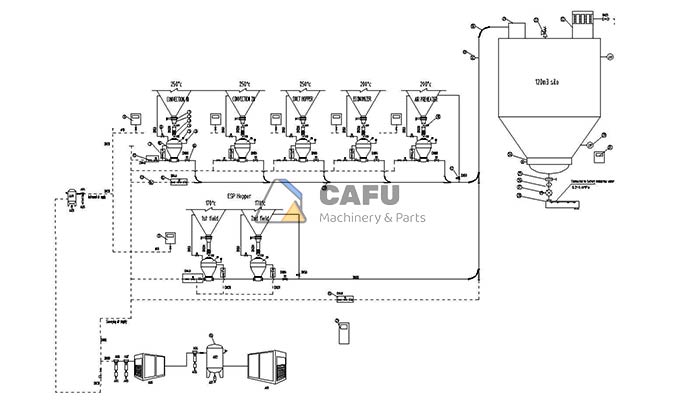

The dense phase ash handling system is an advanced fly ash handling technology with the advantages of high efficiency, energy saving and environmental protection. Its working principle is to use compressed air to transport fly ash in high concentration. This system usually consists of air source equipment and filtration device, dense phase conveying pump (bin pump), conveying pipeline, control device and so on.

Compared with the dilute-phase ash handling system, the dense-phase pneumatic conveying system has the advantages of relatively low energy consumption, low wear of piping, high ash/gas ratio, larger conveying capacity, longer conveying distance and so on. Therefore, it is more suitable for fly ash handling in thermal power plants. The dilute phase ash handling system is more suitable for cases with shorter conveying distance and small conveying capacity, such as small boiler rooms.

In practical applications in thermal power plants, the dense phase ash handling system has the following key features:

High Conveying Efficiency

The ability to handle fly ash at higher speeds and in larger quantities improves productivity.

Lower Energy Consumption

Compared to other ash handling methods, the need for compressed air is relatively low, reducing energy consumption.

Less Wear and Tear on Piping

Due to the high concentration of fly ash, there is less friction and collision between the particles, which reduces friction with the inner wall of the pipe and extends the life of the pipe.

Flexible System Design

Piping can be designed in series or parallel.

High System Stability

The operating process is more stable, with a low failure rate, which reduces the production interruption caused by system failure.

High Degree of Automation

Convenient to implement automation control and remote monitoring, reducing manual operation and improving management efficiency.

The selection of a suitable dense phase ash handling system requires a combination of the following key factors:

1. Ash characteristics

Understand the particle size distribution, density, moisture, temperature and other parameters of the fly ash. If the temperature of the fly ash is high, the system design must consider the use of high temperature resistant valves.

2. Distance and height

Longer conveying distances and greater height differences require the system to have stronger power and pressure support.

If the conveying distance exceeds a certain range, it may be necessary to add a compressed air booster and a clog removal device in the middle of the pipeline.

3. Capacity requirements

Determine the conveying capacity of the system according to the amount of fly ash produced in the production process, and select the appropriate compressed air flow rate, the appropriate volume of the conveying pump and the appropriate size of the conveying pipe according to the conveying volume.

4. Site conditions

Consider the size, layout and other factors of the installation site. The piping design should minimize the number of turns to reduce the operating resistance of the system.

CAFU Machinery has long been engaged in thermal power plant boiler ash removal and comprehensive fly ash utilization project. Our dense phase ash handling system is widely preferred by users of large thermal power plants in various regions for its high quality and reliability.

Now, with just one e-mail from you, we will provide you with a service guarantee including system design, equipment manufacturing and integration, installation supervision and commissioning.