CAFU supplies crusher liners at competitive prices to a diverse range of mining customers, offering a comprehensive solution for crusher wear liners. Our product range includes cone crusher mantle and bowl liners, jaw plates and liners, blow bars and impact plates for impact crushers, and more.

The principal materials used in the manufacture of our crusher liners are as follows:

• High manganese steel.

• Manganese-chromium alloys, including Mn13Cr2, Mn18Cr2, Mn22Cr2, and others.

• Hard alloy.

• We also supply chromium steels.

• Martensitic steels are also available.

• Additionally, we offer metal matrix ceramic composites and other specialized materials.

The following materials can be handled:

• River pebble

• Granite

• Basalt

• Iron ore

• Limestone

• Quartz

• Diabase

• Iron ore

• Gold ore

• Copper ore

We select the most appropriate materials for your specific crushing applications and provide the best product performance for various crusher wear plates through the most appropriate heat treatment process.

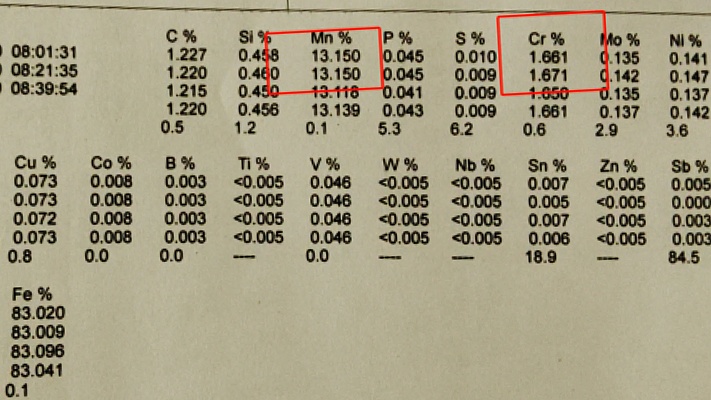

To ensure the wear and impact resistance of our products, we strictly enforce the content ratios of various metallic materials that have an absolute impact on the wear resistance of our products.

We carry out rigorous testing of our products to ensure that the content of various elements meets the standard requirements.

We know that for some alloys, which are extremely costly, an increase of 1% or 0.1% in content means an increase in cost. However, it has always been our quality policy to provide our customers with the highest performing products.

Jaw Crusher Wear Parts

Depending on your working conditions, CAFU can manufacture jaw plates with different tooth shapes and materials.

Jaw crushers are used to crush materials in mining, construction, infrastructure and other sectors.

The jaw crusher has two jaw plates.

One is the fixed jaw, which is fixed vertically on the front wall of the machine frame. The other is the movable jaw, which forms a crushing chamber with the fixed jaw. Since the movable jaw plate periodically reciprocates against the fixed jaw plate, the material will be crushed.

The jaw dies and cheek plates are the most common parts of jaw crushers to wear out. CAFU can make jaw plates with different teeth and materials for your work. Our cast cheek plates are made from manganese and chrome. Our jaws are made from 18% manganese and 3% chrome iron.

In addition to our standard products, we also manufacture custom jaw plates, with the formulation to be specified by the customer.

Our jaw plate is stronger and lasts 10% longer than traditional high manganese steel. Our jaw plate performs well in different working conditions, saving time and money and helping clients improve their economic benefits.

Cone Crusher Wear Parts

CAFU can make matching wear parts for your cone crushers.

The cone crusher has a large crushing ratio, high efficiency, low energy consumption and uniform product size. It crushes medium and fine materials with medium or above hardness. It is used for crushing ores and rocks. Cone crushers are used in many industries, including mining, smelting, building materials.

The motor drives the eccentric shaft to rotate through the transmission devices during operation. The mantle swings under the force of the eccentric shaft. The mantle section near the concave forms the crushing cavity. The material is broken and falls out of the cone crusher because of the impact of the mantle and concave.

The most common parts to wear in a cone crusher are the mantle and concave.

CAFU can make custom cone crusher mantle, concave and other cone crusher parts in manganese-chromium alloy to suit your crusher.

Manganese chrome alloy makes cone crushers wear parts stable, safe and long-lasting.

Impact Crusher Wear Parts

Common jaw crusher spare parts and jaw crusher wear parts include:

• Blow Bars

• Impact Plates

• Breaker Plates

• Side Liners

• Rotor

An impact crusher crushes materials using impact energy. The motor drives the rotor to rotate at high speed. The material hits the blow bars on the rotor and is thrown to the breaker plates, where it is broken again and then rebounds. Go back to the rotor to crush again.

This happens again and again. The material is crushed in three stages and then discharged.

The hammer and liner are the main parts of the impact crusher that wear out.

The blow bars and liners produced by CAFU are primarily composed of high-chromium alloy castings, which undergo a specialized refining process and are suitable for a range of applications. They exhibit an optimal micro-grain structure and sufficient toughness following quenching and tempering heat treatment, with a hardness that can exceed HRC60.

CFAU's high-chromium alloy blow bars and breaker plates have been successfully implemented in numerous impact crushers across dozens of countries worldwide.

Why choose CAFU as your crusher wear parts supplier?

1. Tailor made production, perfect fit for your crusher model;

2. Wide range of materials to choose from;

3. Range of wear resistant products, one-stop supply;

4. Longer service life;

5. We offer more competitive price;

6. More professional service and advice.

CAFU is a trusted supplier of crusher wear parts for operators worldwide. If you require a reliable supplier with prompt service, we can assist.