Ceramic wear plates for chutes and hoppers are plates made of ceramic materials specifically designed to resist wear and abrasion. These plates have excellent wear resistance, hardness and chemical resistance.

They are widely used in various industrial applications where there is significant friction and wear, such as mining, cement production, power generation, and aggregate handling. The ceramic material provides superior protection against abrasive particles, reducing equipment wear and extending component life.

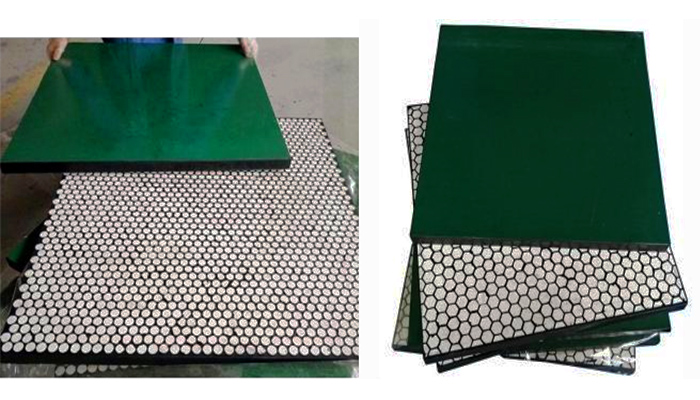

Ceramic wear plates for chutes and hoppers are made from rubber or polyurethane, alumina ceramic sheets, and rubber backing plates laminated by a hot vulcanization process.

There are three general types:

• Ceramic Rubber Composite Lining with CN Bonding Layer

Ceramic rubber composite lining with bonding Layer can be bonded directly to the equipment by adhesive, easy installation and placement, power saving, noise reduction etc.

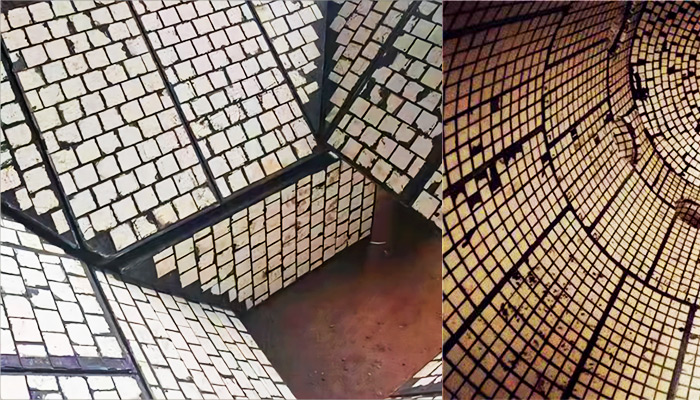

• Ceramic Rubber Composite Lining with Steel Backing Plate and Studs

Ceramic rubber liners can be produced with steel backing plates and studs, and this type of liner can be bolted to the facility.

• Ceramic Polyurethane Wear Liner for Chutes and Hoppers

Ceramic polyurethane composite liner is a liner made of wear-resistant ceramics and vulcanized polyurethane plate, which has strong abrasion, impact and corrosion resistance, and can be used in the range of -40℃-140℃. Installation can be bolted, welded or glued.

Wear-Resistant Ceramic Lining Plates Features:

• High-aluminum ceramic has excellent wear resistance.

• Energy absorbing rubber pads are more impact resistant.

• Extend the service life of the production line, reduce maintenance and downtime.

• Product types available: ceramic and rubber, ceramic and rubber with steel plate, ceramic and polyurethane.

• High alumina ceramic, 92% or 95% AI2O3.

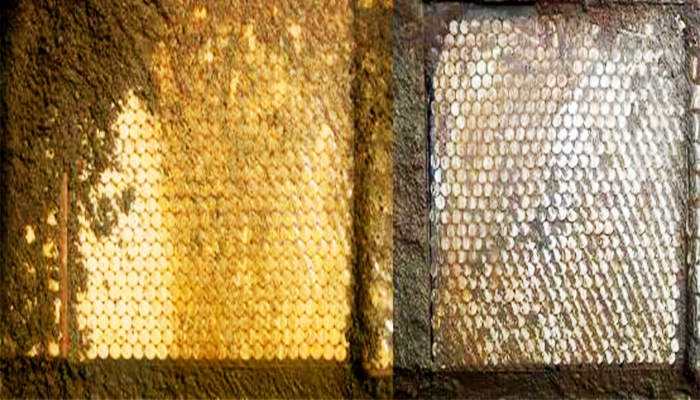

Wear-Resistant Ceramic Lining Plates Applications:

• Power plants

Bucket wheel stacker reclaimer barrel and disk, belt header hopper, raw coal hopper.

• Steel industry

Hopper, silo, belt conveyor skirt, cart tee hopper, receiving hopper, beneficiation hopper under vibrating screen, raw material transportation chute.

• Port

Berth fixed hopper, bucket wheel machine fixed hopper, belt machine transfer station fixed hopper, ship unloader hopper.

• Mining

Various hoppers and chutes

• Coal industry

Hoppers, silos, distribution ports.

• Cement industry

Chutes, hoppers, separator cones and housings.

Common Sizes of Wear-Resistant Ceramic Lining Plates:

| Ceramic Rubber Composite Lining with CN Bonding Layer | |||

| Size | Ceramic Shape | Material Composition & Thickness | Total Thickness (mm) |

| 500∗500∗8 | Square, Cylindrical or Hexagonal | 4mm ceramic and 4mm rubber | 8 |

| 500∗500∗10 | Square, Cylindrical or Hexagonal | 6mm ceramic and 4mm rubber | 10 |

| 500∗500∗14 | Square, Cylindrical or Hexagonal | 10mm ceramic and 4mm rubber | 14 |

| 500∗500∗20 | Square, Cylindrical or Hexagonal | 13mm ceramic and 7mm rubber | 20 |

| 500∗500∗25 | Cylindrical or Hexagonal | 20mm ceramic and 5mm rubber | 25 |

| 500∗500∗30 | Cylindrical or Hexagonal | 25mm ceramic and 5mm rubber | 30 |

| Other sizes are custom made for the specific application. | |||

| Ceramic Rubber Composite Lining with Steel Backing Plate and Studs | ||||

| Total Thickness (mm) | Size (mm) | Ceramic Shape and Size (mm) | Rubber Layer Thickness (mm) | Steel Backing Layer Thickness (mm) |

| 35 | 300∗300∗35, 500∗500∗35 | ∅21∗21 cylinder | 8 | 6 |

| 35 | 300∗300∗35, 500∗500∗35 | ∅21∗25 cylinder | 5 | 5 |

| 50 | 300∗300∗50, 500∗500∗50 | ∅32∗32 cylinder | 12 | 6 |

| 30 | 500∗500∗30 | 48∗48∗20 cube, 80∗30∗20 cube | 5 | 5 |

| 45 | 500∗500∗45 | 48∗48∗35 cube, 80∗30∗35 cube | 5 | 5 |

| 50 | 500∗500∗50 | 48∗48∗38/40 cube, 80∗30∗38/40 cube | 6/5 | 6/5 |

| Other sizes are custom made for the specific application. | ||||

Customized Service:

• Reliable quality

• Cost-effective

• Full technical support

• OEM available

• Product test reports