Supply of high performance cement plant wear parts for cement plants has been one of Cafu's main business. The scope of supply includes wear parts for cement ball mills and vertical mills, high temperature resistant linings and parts for rotary kilns, grid plates for cooling, wear parts for crushers, corrosion resistant pipes, conveyor wear parts, etc. Major users include well-known cement producers in South America, the Middle East, Africa, Southeast Asia and Europe.

Download Brochure⇒Cement Plant Spare Parts Brochure

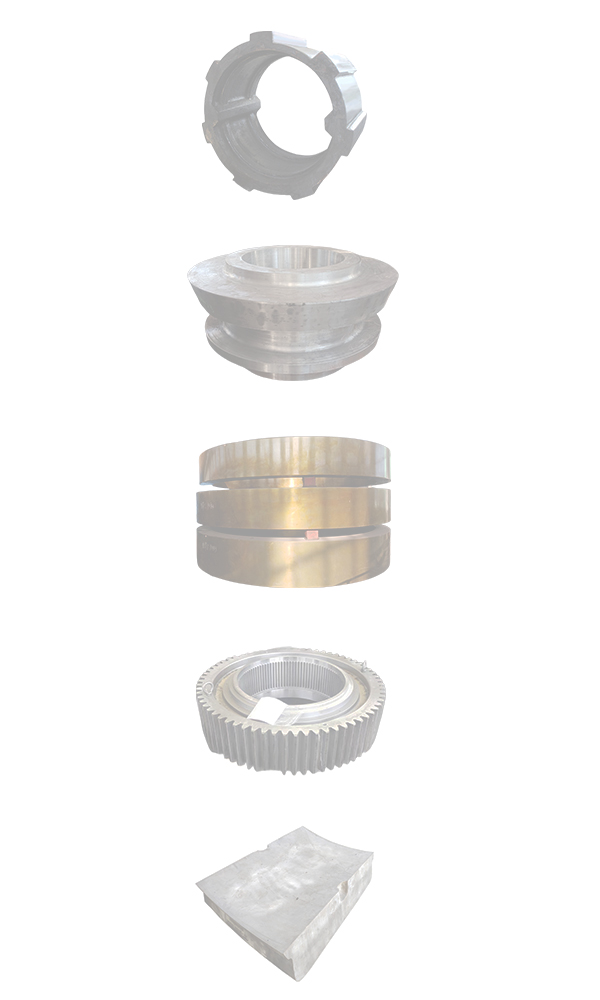

Major cement plant wear parts include:

• Ball Mill Trunnion

• Girth Gear

• Alloy Tiles

• Support Roller of Rotary Kiln

• Kiln Tyre

• Thrust Roller

• Rotor of Separator

• Roller Shell

• Grinding Roller

• Pinion Assembly

• Cyclone Skirts

• Mill Contrarotating Ring

• Liner of Mill

• Hydraulic Thrust Roller For Rotary Kiln

• Crusher Liner

• Housing Bottom In Vertical Mill

• Sealing Plate In Vertical Mill

• Track Segment In Vertical Mill

• Buffer Plates In Vertical Mill

• Mill Housing In Vertical Mill

• Lining For Mill Housing

Please note: this is not a comprehensive list of available products. Please contact your account manager for further details.

Product type:

• Cast parts

• Forging parts

• Machined parts

• Welded parts

• Other cement plant spare parts

Material properties:

• Wear-resistant

• High temperature resistance

• Corrosion resistant

Customised Service:

• Reliable quality

We understand the complexity of cement industry equipment, and our team of engineers is therefore constantly striving to maintain a rational working attitude at all times, to face the challenges of the job and to provide solutions that will satisfy our customers. The cement plant spares supplied by CAFU are designed to withstand a variety of environments, including high-temperature applications, resistance to strong shocks, and long service life.

• Cost-effective

CAFU have consistently sought to provide customers with the highest quality cement plant wear parts at the most competitive prices. We share a common philosophy of achieving project success and creating higher value returns for our end-users.

• Product test reports

Includes hardness testing, chemical elemental analysis of materials, NDT, and material quality certificates.