The carburised round steel chain undergoes a three-stage process consisting of carburising, quenching and tempering, resulting in a product with high wear resistance, high strength and good toughness. Hence, it is suitable for use in various demanding industrial sectors, such as mining, lifting and transportation, electric power and the chemical industry. In these applications, the chain can be relied on to perform essential material transport functions.

Download Product Brochure ⇒ Round Steel Chains and Chain Shackle and Fittings

Carburized Round Steel Chain Production Process

1. Carburizing treatment: The round link chain to be treated is put in a specific temperature environment to allow carbon atoms to penetrate into the surface layer of the chain material. This process is usually divided into a strong infiltration stage and a diffusion stage. The strong infiltration stage makes the surface of the material quickly absorb a large number of carbon atoms and increase the carbon concentration. The diffusion stage lets the carbon atoms further diffuse into the material so that the carbon concentration is more evenly distributed, thus forming a certain thickness of the carburized layer.

2. Quenching treatment: After carburizing, the rings are quenched. The rapid cooling makes the material's organizational structure change, forming a martensitic structure with high hardness, which improves the strength and hardness of the chain.

3. Tempering treatment: The chain will be tempered after quenching. Tempering can reduce the brittleness of the chain and improve the toughness. Meanwhile, it can eliminate the internal stresses produced during the quenching process and improve the comprehensive performance of the chain. Two tempering treatments can further optimize the performance of the chain.

Carburized Chain Performance Characteristics

1. High abrasion resistance: The carburized layer formed by carburizing treatment has high hardness, which can effectively resist abrasion and prolong the service life of the chain. In some occasions with high requirements for abrasion resistance, such as mining, lifting, slag removal and other operations, the advantages of the carburized round link chain's abrasion resistance are especially obvious.

2. High strength: Through the reasonable heat treatment process, the organizational structure of the chain material is optimized so that it has high strength and can withstand large tensile force and load.

3. Good toughness: The chain has good toughness after tempering treatment and is not easy to break when subjected to impact load, ensuring the safety of the chain under complicated working conditions.

Main Application Fields

1. Cement and mining industry: It is a commonly used traction chain in coal mines, cement plant, etc. It is used in scraper conveyors, bucket elevators and other equipment to transport coal, ore and other materials.

2. Electricity and chemical industry: It is used in electric power, chemical industry and other industries in slag removal machines, slag conveyor and other equipment and can run reliably in harsh working environments.

Material: Alloy Steel (23MnNiMoCr54, etc.)

Size and Mechanical Property

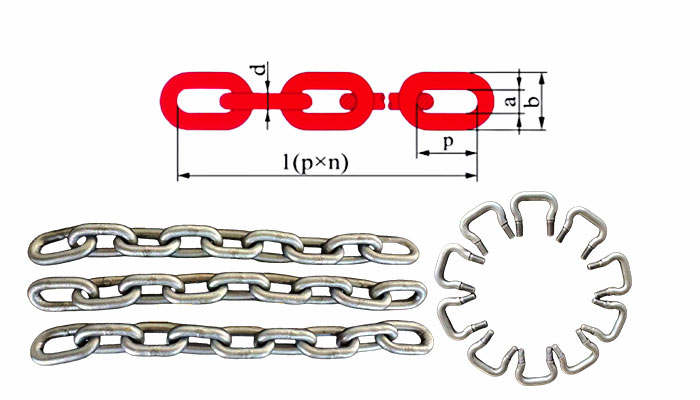

| Spec. d×p (mm) |

Width Min. a (mm) |

width Max. b (mm) |

Mass (kg/m≈) |

Min. Breaking force (kN) |

| 13×45 | 18 | 47 | 4.2 | 167 |

| 14×45 | 18 | 48 | 4.4 | 190 |

| 14×50 | 17 | 48 | 4 | 190 |

| 16×56 | 22 | 58 | 5.2 | 250 |

| 16×64 | 20 | 55 | 5.3 | 250 |

| 18×50 | 21 | 60 | 6.9 | 320 |

| 18×63 | 24 | 65 | 6.83 | 320 |

| 18×64 | 21 | 60 | 6.6 | 320 |

| 18×66 | 28 | 67 | 6.7 | 320 |

| 18×80 | 28 | 67 | 6.25 | 320 |

| 18×82 | 21 | 60 | 6 | 320 |

| 20×55 | 25 | 69 | 9.1 | 390 |

| 20×70 | 27 | 72 | 8.2 | 390 |

| 22×64 | 29 | 75 | 10.6 | 480 |

| 22×70 | 27 | 72.5 | 10.57 | 480 |

| 22×76 | 26 | 74 | 10.3 | 480 |

| 22×80 | 31 | 83 | 10 | 480 |

| 22×86 | 26 | 74 | 9.5 | 480 |

| 24×75 | 32 | 82 | 12.5 | 570 |

| 24×85.3 | 30 | 82 | 11.7 | 570 |

| 26×81 | 46 | 101 | 15.2 | 670 |

| 26×91 | 35 | 94 | 14.3 | 670 |

| 26×92 | 30 | 86 | 13.7 | 670 |

| 30×105 | 39 | 108 | 18.7 | 890 |

| 30×108 | 34 | 98 | 18 | 890 |

| 34×126 | 38 | 109 | 22.7 | 1140 |

| 34×136 | 39 | 113 | 23.8 | 1140 |

| 36×126 | 47 | 130 | 26.7 | 1280 |

| 42×147 | 55 | 151 | 35.6 | 1750 |

Customization standards: ISO, DIN, BS, GB and other standards

Product Advantage:

• Utilization of high-quality raw materials.

• High strength and excellent toughness.

• High capacity for absorbing impact loads.

• 100% factory testing.

• Employment of advanced production equipment.

• Adoption of advanced heat treatment process and surface anti-rust treatment.

We offer replacement products of carburised round steel chains for cement plants and mining industries. If you need further information or would like to discuss your specific requirements in greater detail, please feel free to contact us.