The ball mill liner is a crucial component of the ball milling equipment. The most commonly used materials for ball mill liners are high manganese steel, including high chrome cast iron and other materials. The installation of mill liners inside the mill ensures that there is no direct contact between the grinding media and the mill shell. This reduces wear and tear on the mill shell, thereby prolonging the service life of the ball mill. Additionally, the shape of the mill liner can affect the movement of the grinding media, thereby optimizing the grinding effect.

Our ball mill liners are designed to offer superior wear resistance, impact resistance and a long lifespan. The main materials used include high manganese steel, high chromium cast iron, manganese chromium alloy, chrome, and Ni-hard steel. Furthermore, we can also create a bespoke mill liner to meet the specific requirements of our customers.

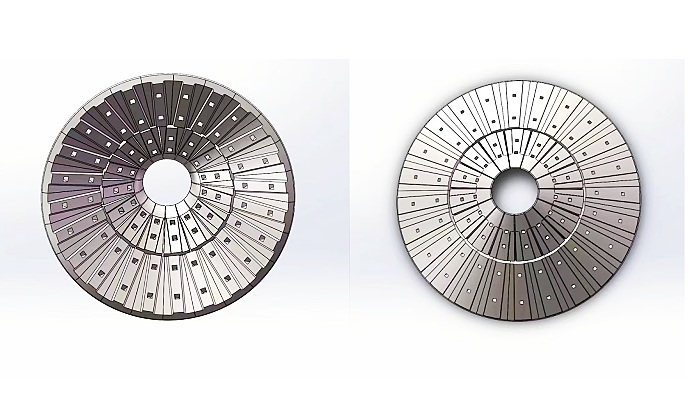

We appreciate that installing mill liners can be a challenging process. That's why we create each custom mill liner through a rigorous 3D design process. This ensures that all production dimensions align with the installation requirements of the original mill. This allows our customers to easily and accurately install the liners on their mills.

The mill liners we supply include ball mill liners, rod mill liners, SAG mill liners, and AG mill liners. With many years of experience in the industry, CAFU is well-positioned to assist users in modifying the shape of the liner to optimise the grinding effect of the material.

As a professional supplier to the cement and mining industry, we can provide reliable and cost-effective wear-resistant liners to a diverse range of customers. Many users have reported that our high manganese steel mill liners typically extend their service life by 10-20% due to their high product quality, thereby reducing the operating costs of cement and mining plants.

Our products are suitable for a number of applications, including:

• Cement mills

• Ball mills

• Rod mills

• AG and SAG mills

As a leading supplier of engineered mill wear spares, we have extensive experience in the different designs and types of mill liners and how to select the best material and profile for your grinding material. Our design department works closely with users to develop bespoke liners that meet the specific requirements of AG/SAG, ball and rod mills.

So far, we have established co-operation ping with users in industries including cement plants, mining, including:

• Cement plant

• Mineral processing plant

• Fluorspar processing enterprises

• Lithium ore processing enterprises

• Sand making plant

• Steel slag production enterprises, etc.

For further enquiry on custom discounted quote for mill liner, please feel free to contact our customer service personnel.