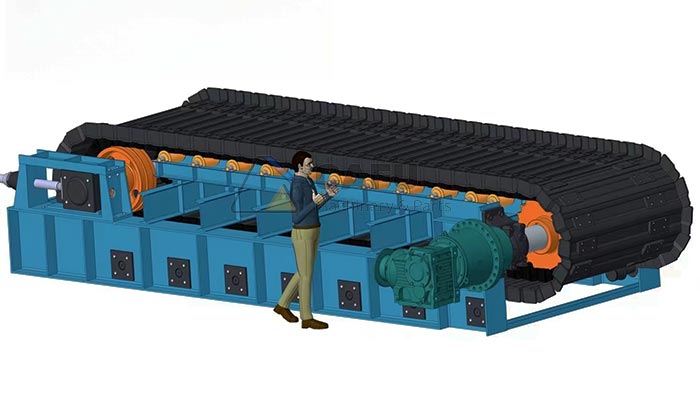

Cafu's standard type heavy apron feeder is manufactured using advanced engineering technology and high-quality materials, ensuring outstanding durability and reliability. Its rugged construction is able to withstand harsh working environments and intense continuous operation, guaranteeing long-term stability. In terms of performance, Cafu's apron feeder demonstrates excellent feeding capability and precise control. It can convey wet, sticky or dry material at a uniform and stable rate, effectively avoiding material clogging and uneven feeding problems.

Download Brochure⇒CFH Series Apron Feeder Brochure

CAFU's standard type heavy apron feeder is the optimal solution for robust and reliable performance. The equipment is crafted with the highest quality, durability, and reliability standards, capable of withstanding shocks from heavy loads and operating in a wide range of environments.

Our standard heavy duty apron feedersr is designed to offer a reliable and economical solution.

• The product features a robust design structure, which ensures optimal performance in heavy load conditions.

• The product is highly reliable and operates effectively.

• The product has been designed to consume low levels of energy and to have low operating costs.

• The product offers high stability.

• The product is designed for easy maintenance.

Features of Standard Type Heavy Apron Feeder

• Crawler excavator chain

• Chain plate is made of wear-resistant steel or cast wear-resistant steel.

• Double-row drag chain wheel structure

• UCFX series heavy duty bearings

• Heavy duty disc spring tensioning

• Drive can be electrically or hydraulically driven

• Bilateral drive (optional)

• Uses high strength sprockets

• Can be used on flat or up to 20° slopes

• Hopper mounting holes in frame design for weld-free installation

• Customised hoppers with optional wear-resistant liners

CAFU Machinery's CFH series standard type heavy duty apron feeder stands for ruggedness. Our strong commitment to quality and attention to detail in design and manufacture guarantees the longest possible service life.

The Latest Crawler Chain Track Design

The crawler chain track apron feeder, with its tracked structure, requires minimal maintenance. All components are "sealed for life and self-lubricating", eliminating the need for regular lubrication. This ensures that our customers enjoy long-term reliability and minimal downtime.

The CFH series apron feeder is the optimal choice for feeding aggregates that are chunky, lumpy, abrasive, and heavy, even in wet, sticky, or frozen operating environments. It is suitable for a wide range of applications.

Main Applications

• Cement Industry

• Rock Crushing

• Topsoil

• Copper Ore

• Iron Ore

• Bauxite

• Coal Mines

• Limestone Ore

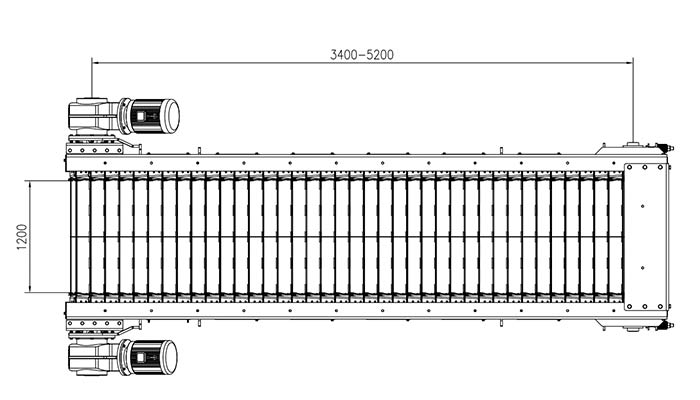

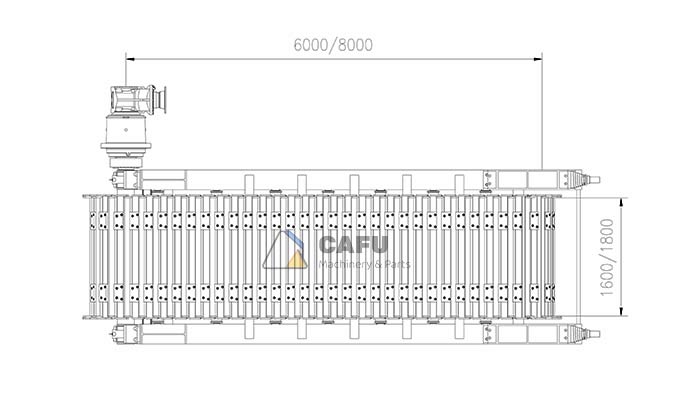

CFH Series Apron Feeder Standard Sizes

• 1200mm standard width

• 1600 and 1800mm standard width

| Type | Size(mm) | Max. Feed Size(mm) | Capacity(tph) | Speed(m/s) |

| CFH1234 | 1200*3400 | 600 | 250-500 | 0-0.3 |

| CFH1238 | 1200*3800 | 600 | 250-500 | |

| CFH1243 | 1200*4300 | 600 | 250-500 | |

| CFH1252 | 1200*5200 | 600 | 250-500 | |

| CFH1660 | 1600*6000 | 800 | 600-800 | 0-0.2 |

| CFH1680 | 1600*8000 | 800 | 600-800 | |

| CFH1860 | 1800*6000 | 900 | 800-1000 | |

| CFH1880 | 1800*8000 | 900 | 800-1000 |

Three Reasons Choose CAFU-Our Core Advantages

CFH Series Sstandard Type Heavy Duty Apron Feeder Selection Guide

• Material to be processed.

• Processing capacity (t/h).

• Material density (t/m³).

• Machine length (m).

• Machine inclination (°).

• Maximum particle size (mm).

• What equipment is used to feed material into the apron feeder?

• What equipment is used to discharge material from the apron feeder?

• Working power supply (V/HZ).

• Quantity required.

• Whether hopper is needed.

If you need to order an apron feeder, please send us the "Heavy Duty Apron Feeder Selection Guide" immediately and we will provide you with the best solution in a timely manner.

Download