We provide economically reliable crushers for the aggregate crushing solution with a lower total cost of ownership. Our product range includes jaw crushers, impact crushers, hammer crushers, roller crushers and cone crushers. These crushers are widely used in the fine crushing, medium crushing and coarse crushing operations of ores and rocks.

1. Cost-Effective Jaw Crusher: Ideal for Crushing Operations

The jaw crusher we offer is an economical and cost-effective crushing equipment in the crushing industry. As a primary crusher functioning based on the principle of extrusion, it can break large rocks and ores into particles of a defined size during the crushing process. Its robust construction and reliable operation make it an indispensable crusher for the quarrying, mining and construction industries. It excels in crushing performance, especially in terms of crushing efficiency and product size control, and is well suited to a wide range of material processing requirements.

Technical Parameters:

| Model | Feed Opening Size(mm) | Max. Feeding Size(mm) | Adjustment Range of Discharge Opening(mm) | Power(kw) | Capacity(t/h) | Dimensions(LxWxH) (mm) |

| PEX 250x1200 | 250x1200 | 200 | 20-60 | 37 | 20-70 | 1670x2190x1430 |

| PEX 300x1300 | 300x1300 | 250 | 20-90 | 55 | 30-90 | 1870x2450x1650 |

| PEX 500x1500 | 500x1500 | 450 | 40-100 | 45 | 50-120 | 2070x2650x1750 |

| PE 250x400 | 250x400 | 210 | 20-70 | 15 | 5-21 | 1100x1030x1285 |

| PE 400x600 | 400x600 | 350 | 40-100 | 30 | 14-36 | 1700x1732x1656 |

| PE 500x750 | 500x750 | 450 | 50-100 | 45 | 30-80 | 2035x1920x2000 |

| PE 600x900 | 600x900 | 550 | 65-160 | 75 | 56-190 | 2280x2245x2320 |

| PE 750x1060 | 750x1060 | 700 | 80-180 | 110 | 108-256 | 2530x2370x2785 |

| PE 900x1200 | 900x1200 | 800 | 100-200 | 132 | 185-395 | 3160x2770x3160 |

| PE 1200x1500 | 1200x1500 | 1100 | 150-350 | 200 | 400-800 | 4590x3730x3843 |

| Note: Capacity may vary due to different materials and other factors. The above technical parameters are for reference only. Refer to the actual product for the equipment's performance parameters. | ||||||

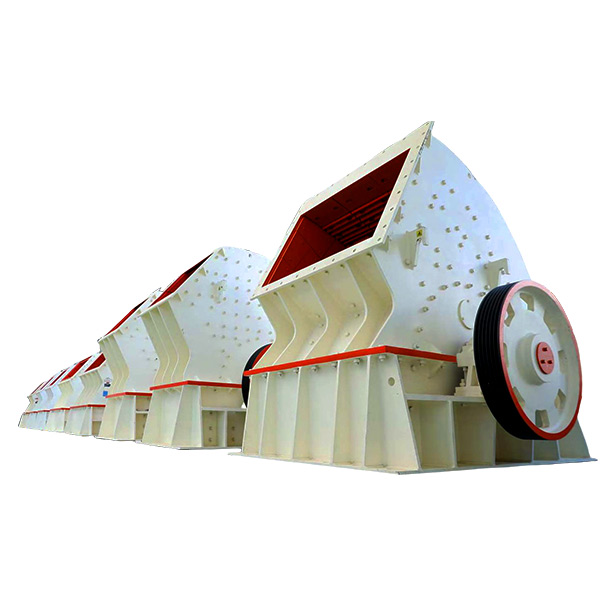

2. High-Performance Impact Crusher: Ideal for Crushing and Recycling

Our impact crusher, a top-notch impact crushing equipment, is highly effective and offers unparalleled performance in the crushing industry. It's specifically designed to handle a diverse range of materials like rocks, ores and recycled concrete. By leveraging the impact force, it can effectively break these materials down into smaller, more uniform particles. Due to its high crushing ratio and efficient operation, this impact crusher is widely utilized in mining operations, construction projects and waste recycling sectors, where it performs excellently for secondary and fine crushing tasks.

Technical Parameters:

| Model | Spec. (mm) | Feed Opening Size(mm) | Max. Feeding Size(mm) | Power(kw) | Capacity(t/h) | Dimensions(LxWxH) (mm) |

| FJP 1010 | Φ 1000x1000 | 1170x465 | 350 | 75 | 50-80 | 2532x1985x2196 |

| FJP 1214 | Φ 1200x1400 | 1440x465 | 350 | 132 | 100-160 | 2580x2400x2810 |

| FJP 1315 | Φ 1300x1500 | 1532x560 | 500 | 160 | 140-200 | 2840x2748x2556 |

| FJP 1520 | Φ 1500x2000 | 1580x696 | 500 | 315 | 280-350 | 3800x3350x3250 |

| Note: Capacity may vary due to different materials and other factors. The above technical parameters are for reference only. Refer to the actual product for the equipment's performance parameters. | ||||||

3. High-Performance Hammer Crusher: Ideal for Crushing Medium-Hard Materials

The hammer crusher, an essential hammer crushing equipment in the field of crushing, showcases outstanding performance. It is primarily utilized for the crushing of diverse medium-hard and brittle materials, such as limestone, coal, and shale. Thanks to the high-speed rotation of the hammers, these materials are effectively fragmented. Its simple structure and reliable operation have led to its wide application in cement production, chemical processing, and power generation industries, where it plays a significant role in both primary and secondary crushing processes.

Technical Parameters:

| Model | Spec. (mm) | Feed Opening Size(mm) | Max. Feeding Size(mm) | Power(kw) | Capacity(t/h) | Dimensions(LxWxH) (mm) |

| 1615 | 1600x1500 | 1400x1000 | 550 | 200x2 | 200-550 | 3370x2925x2750 |

| 1716 | 1700x1600 | 1640x1300 | 600 | 250x2 | 450-850 | 3520x3000x3210 |

| 1720 | 1700x2000 | 1980x1300 | 650 | 400x2 | 500-1000 | 3670x3390x3330 |

| 1920 | 1900x2000 | 1850x1600 | 750 | 500x2 | 800-1500 | 3730x3330x4450 |

| Note: Capacity may vary due to different materials and other factors. The above technical parameters are for reference only. Refer to the actual product for the equipment's performance parameters. | ||||||

4. High-Performance Roller Crusher: Key to Precision Crushing in Mining, Chemical & Building Materials

The advanced roller crusher represents a significant advancement in the field of crushing equipment, offering a highly efficient and innovative crushing solution. Our roller crusher model has been meticulously crafted to effectively process a wide range of materials that necessitate a delicate and uniform reduction, such as coal, sand, limestone, and certain soft ores. The rollers, which rotate in opposite directions, exert a gentle squeezing and crushing force on the materials positioned between them, thereby achieving precise size reduction. This reliable roller crusher is widely adopted in various aspects of the mining industry, especially in iron ore beneficiation and copper ore beneficiation. It also plays a vital role in plastic chemical raw material processing and concrete building materials aggregate production. It plays a crucial role in secondary and fine crushing operations, consistently offering excellent performance across these diverse applications.

Technical Parameters:

| Model | Max. Feeding Size(mm) | Discharge Size(mm) | Power(kw) | Capacity (t/h) | Dimensions(LxWxH) (mm) | Weights(kg) |

| 2PGQ400x250 | 25 | 1-8 | 5.2x2 | 5-10 | 1215x834x816 | 1500 |

| 2PGQ610x400 | 36 | 2-9 | 15x2 | 3-9 | 1785x2365x1415 | 4500 |

| 2PGQ750x500 | 40 | 2-10 | 18.5x2 | 5-12 | 2720x2700x1400 | 10800 |

| 2PGQ750x700 | 40 | 2-10 | 22x2 | 6-16 | 2800x3987x1705 | 12200 |

| 2PGQ900x500 | 40 | 2-10 | 22x2 | 9-30 | 2750x1790x2065 | 15000 |

| 2PGQ900x900 | 40 | 2-10 | 37x2 | 11-45 | 2750x2180x2065 | 16800 |

| 2PGQ900x1200 | 40 | 3-10 | 55x2 | 15-60 | 2750x2480x2065 | 20800 |

| 2PGQ1200x1000 | 40 | 3-12 | 55x2 | 10-50 | 3690x3430x2700 | 46800 |

| 2PGQ1200x1200 | 40 | 3-12 | 75x2 | 18-68 | 3690x3630x2700 | 48600 |

| Note: Capacity may vary due to different materials and other factors. The above technical parameters are for reference only. Refer to the actual product for the equipment's performance parameters. | ||||||

5. High-Efficiency Cone Crusher: Ideal for Secondary & Fine Crushing

Discover our cone crusher that stands out with its excellent performance in secondary and fine crushing of ores and rocks. Widely used in mining, quarrying, and construction, it improves aggregate quality and boosts production efficiency.

The high-performance cone crusher represents a pivotal piece of machinery, playing a significant role in the domain of crushing. Our cone crusher is mainly employed for the secondary and fine crushing of a diverse range of ores and rocks. Thanks to its advanced crushing structure, it enables the production of well-shaped and uniformly sized products through high-precision crushing and efficient size control. This cone crusher is highly versatile and finds wide application in various sectors, such as mining activities, quarrying operations, and construction projects. Besides improving the quality of the final aggregates, it also remarkably enhances production efficiency, making it an essential choice for related industries.

Technical Parameters:

| Model | Dia. of Moving Cone(mm) | Chamber Type | Max. Feeding Size(mm) | Adjustment Range of Discharge Opening(mm) | Power(kw) | Main shaft speed(r/min) | Capacity (t/h) | Dimensions(LxWxH) (mm) | Weights(≈kg) |

| CS-75B | 25 | Fine type | 83 | 9-22 | 75 | 580 | 45-91 | 2820x1880x2165 | 15000 |

| Coarse type | 159 | 13-38 | 59-163 | ||||||

| CS-110B | 40 | Fine type | 127 | 9-31 | 110 | 485 | 63-188 | 2820x1975x2650 | 20000 |

| Medium type | 156 | 13-38 | 100-200 | ||||||

| Coarse type | 178 | 19-51 | 140-308 | ||||||

| CS-160B | 40 | Fine type | 109 | 13-31 | 185 | 485 | 109-180 | 2800x2342x2688 | 27000 |

| Medium type | 188 | 16-38 | 130-250 | ||||||

| Coarse type | 216 | 19-51 | 172-349 | ||||||

| Note: Capacity may vary due to different materials and other factors. The above technical parameters are for reference only. Refer to the actual product for the equipment's performance parameters. | |||||||||

• Contact Us to Customize Your High-Efficient Crushing Solutions

Our professional team is dedicated to providing personalized services. We will work closely with you to understand your exact demands, such as the types of materials to be crushed, the desired output size, and production capacity. Based on these details, we'll customize a highly efficient crushing solution tailored just for you.